Green tech boosts SZ's smart growth

Writer: Chen Xiaochun | Editor: Zhang Chanwen | From: Shenzhen Daily | Updated: 2022-10-11

A+ A- Print

Editor’s Note

编者按

Shenzhen Daily has joined hands with the Information Office of Shenzhen Municipal People's Government to launch a series of reports titled “Decade of Transformation,” to tell the story of Shenzhen in the eyes of expats. Rafael Saavedra, a popular YouTuber who has been living and working in China for seven years, will host the series, showing you Shenzhen, a dynamic and energetic city from the perspective of 60 expats. This is the second story of the series.

由深圳市人民政府新闻办公室与英文《深圳日报》(Shenzhen Daily)共同策划推出的系列全媒体国际传播作品《我们这10年:湾区老外说变化(Decade of Transformation)》已在各大主流媒体和互联网平台正式上线,该系列将集中展示过去十年以来深圳在各个领域所取得的伟大成就。此次系列作品中,在中国工作和生活了七年的知名网络博主Rafael Saavedra将向大家介绍60位外籍人士,通过他们的脚步和镜头记录和观察一座行进中的中国年轻都市。敬请垂注!

Profile

人物简介

Italian Marco Morea and German Sebastian Hardt both have been working for Bosch Group for a long time and decided to move to the company’s Shenzhen location. Under their leadership, the Bosch Shenzhen plant has invested strongly in its support of the city’s green transformation.

博世深圳工厂的意大利籍高管Marco Morea和德国籍高管Sebastian Hardt都在博世集团工作了很长时间,两人不约而同地选择来深继续为博世工作。在他们的带领下,博世深圳工厂投入大量资金,助力深圳企业发展绿色转型。

Video and photos by Lin Jianping except otherwise stated.

摄影及视频制作:林建平

Shenzhen is planning a new model of smart urban growth with green wisdom, insisting on an ecological priority. The city is strengthening its integration of land and sea transportation, together with regional ecological joint prevention and treatment to enhance disaster prevention capacity. The city is also working to develop green industries, creating a green and healthy living environment and building a new pattern of green development with the intent of attaining carbon peak and carbon neutrality goals.

深圳以绿色智慧谋划城市智慧增长新模式,坚持生态优先,加强陆海统筹,强化区域生态联防共治,提升灾害防御能力,发展绿色产业,以碳达峰和碳中和为契机构建绿色发展新格局。

A view of the city from Yangtai Mountain. Liu Xudong 从羊台山看城市风光。刘旭东摄

Having achieved great economic success over the past decades, Shenzhen has gone all out to transform itself into one of China’s most sustainable cities. This cannot be done without the support of companies contributing to the city.

深圳在过去几十年中取得了巨大的经济发展成就,与此同时,它全力以赴抓好生态环境保护工作,并成功转型为中国最可持续发展的城市之一,这一切成就也离不开在深企业的大力支持。

The Bosch Shenzhen plant is among those that have powerfully invested to support the city’s efforts toward environmental protection.

博世深圳工厂就是全力投入推动深圳打造生态友好型社会的一个典型代表。

Shenzhen, a modern city with high tech

深圳,一座高科技现代化都市

Italian Marco Morea, 50, and German Sebastian Hardt, 41, have been working for Bosch Group for a long time and decided to move to the company’s Shenzhen location.

50岁的意大利籍高管Marco Morea和41岁的德国籍高管Sebastian Hardt都在博世集团工作了很长时间,两人不约而同地选择来深继续为博世工作。

Marco Morea (L) and Sebastian Hardt pose for a photo at the Bosch Shenzhen plant. Marco Morea(左)和Sebastian Hardt在博世深圳工厂合影。

Group for 25 years in different locations around the globe. After working for some years, he applied for a higher position and was designated as the plant manager in Taiwan in 2018. This lean manufacturing specialist moved to Shenzhen from Taiwan in March 2020.

Morea是博世深圳工厂的厂长,他在博世集团世界各地的分部工作了25年。在博世工作了一些时间后,他在集团内部申请了更高的职位,并于2018年被任命为博世台湾工厂的厂长。2020年3月,这位精益生产专家从台湾搬到了深圳。

Marco Morea works in his office. Marco Morea在办公室工作。

Morea, plant manager of the Bosch Shenzhen plant, has been working for Bosch “The city is a quite developed and west-oriented city. That’s why you feel like you were in Europe, because of the whole environment,” Morea said.

“深圳是一座高度发达的城市,这座城市国际化程度很高。城市整体的环境让你仿佛置身于欧洲。”Morea说道。

As for Hardt, commercial director of the Bosch Shenzhen plant, he came to Shenzhen in November 2019 after working for Bosch for 11 years. “I came to China because it is a great opportunity, professionally, to become a commercial director at a manufacturing site,” he told Shenzhen Daily.

Hardt是博世深圳工厂的商务总监,在博世集团工作11年后,他于2019年11月来到深圳。“我选择来中国是因为从职业发展的角度来说,这是一个很好的机会,因为我可以在一个生产基地担任一名商务经理。”他告诉英文《深圳日报》。

Sebastian Hardt receives an exclusive interview with Shenzhen Daily in his office. Sebastian Hardt在办公室接受英文《深圳日报》专访。

“I grew up in a very small village with 3,500 people, and then you come to a big city like Shenzhen with, I don’t know, 18 million people, so of course it’s big, it’s loud, and it’s sometimes a little hectic. But when you live here, you of course also experience all the convenience and the positive things of living in a big city,” Hardt said.

“我在一个只有3500人的小村庄长大,所以来到像深圳这样一座大约有1800万人的城市,对我来说,这是一座巨大的都市,车水马龙,大家很忙碌,生活节奏比较快。当然,如果住在这里,你可以体验到生活在大城市中的便利和好处。”Hardt说道。

Hardt loves ordering things online and enjoys the life here. “I like the technology in Shenzhen. You do everything with your phone. You pay everything with your phone. And I love all the electric cars in Shenzhen. I am very impressed that basically all the taxis are electric vehicles. I like the public transportation. So after living here for a while, I’ve come to enjoy the advantages of living in a very big, modern city.”

Hardt很喜欢网上购物,他非常享受在这里的生活。“我对深圳的高科技非常着迷,手机在这里无所不能,你可以用手机支付;我也很喜欢深圳的电动汽车,让我印象深刻的是,这里几乎所有出租车都是电动汽车,我也喜欢这里便利的公共交通。所以,在深圳住了一段时间后,我享受着在一座现代大都市生活所带来的便利。”

A view of the Bosch Shenzhen plant. Courtesy of the plant. 博世深圳工厂一景。

“When you look at the overall picture, let’s say the high-end technology, I think there’s no better place to do the business than here in Shenzhen. You have all these very famous companies, you have a lot of start-ups, and you of course also attract the right people. You have all the big companies including Huawei, BYD… and you could name all of them, they are all located in Shenzhen,” he said.

“深圳是高端技术业务发展的不二之选。深圳拥有很多知名公司、初创企业,成为全球科技人才向往之地。深圳诞生了众多大型企业,包括华为、比亚迪等。”他说道。

Investment in clean manufacturing

全心投入致力于清洁生产

Shenzhen is sparing no efforts to improve its ecological environment and focuses more on developing industries such as network and communications, advanced manufacturing, fashion, intelligent robotics, and design and bio-medicine. Similarly, traditional manufacturers like Bosch Shenzhen plant are also committed to this green transformation.

深圳不遗余力推进生态文明建设,把生态环境保护摆在与经济发展同等重要的位置,着重发展网络和通信、先进制造业、时尚、智能机器人、设计和生物医药等产业。像博世深圳工厂这样的传统制造商都在积极实现绿色转型。

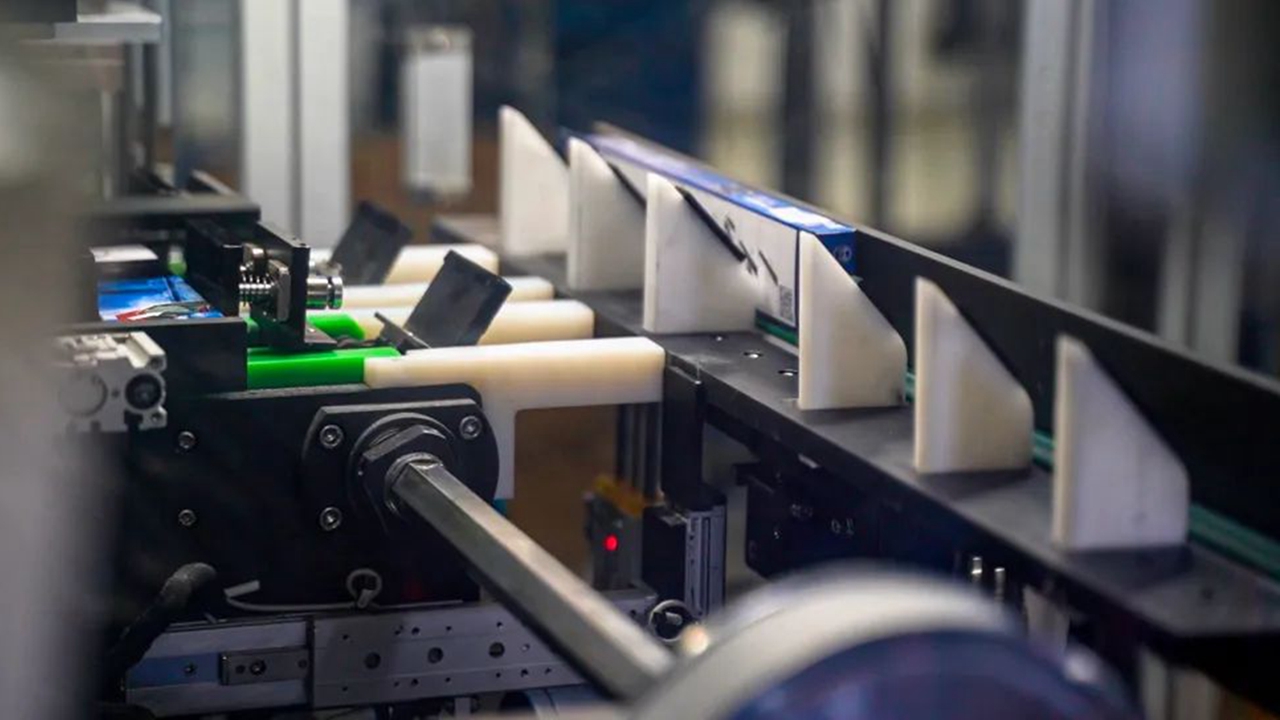

Products in boxes are seen on a production line in the Bosch Shenzhen plant. 博世深圳工厂生产线上的产品。

“Here in our plant, we produce our own rubber for our wiper blades. We also have a painting facility and a painting line, which means there are a lot of potential environmental hazards, a lot of garbage, and we can feel that the restrictions are getting stricter,” Hardt said.

“我们工厂生产雨刷和雨刷所需要的橡胶,另外也有一个涂装设备和一条涂装线。如处理不当,其实有很多潜在的环境风险,会产生很多垃圾,我们也感受到在深圳各类限制越来越严格。”Hardt解释说。

“Currently the Shenzhen government advocates clean manufacturing, which I can fully understand, and to be honest, I also support, because they want Shenzhen to be an IT city and a clean manufacturing site. We have rubber production. We have a painting process. We were not really, let me say, the cleanest manufacturing site before,” Morea said.

“如今,深圳追求发展清洁生产,我完全理解,也全力支持。因为深圳想成为科技型城市,想要发展清洁的制造业。我们有橡胶的加工生产,还有喷漆工艺,所以之前我们并不是最’干净’的制造商。”Morea评论道。

Marco Morea (R) and Sebastian Hardt introduce their plant to Shenzhen Daily reporters. Marco Morea(左)和Sebastian Hardt向记者展示他们的一个产品。

According to Hardt, Bosch is very famous worldwide for its focus on environmental protection and social responsibilities. “It’s basically one of our core values to try to get better and we are carbon neutral within Bosch, and of course this is the achievement of each location,” he said.

Hardt介绍说,博世集团在全球以注重环境保护和承担社会责任而闻名。“实际上,我们的一个核心价值观就是努力做得更好,博世集团内部也实现了碳中和的目标,当然这是博世集团在世界各地的分部共同努力一起取得的成就。”他说道。

“Since we came here two to three years ago, my colleague and I have been paying attention to these issues: where we can have additional cost savings and energy savings, how we can go more into green energy sources instead of traditional energy sources. We also planned, for example, to put solar panels on our roof. So, there were a lot of activities. We changed old machines and replaced them with new machines that consume less energy,” Hardt said.

“从两三年前我们第一次来到这里开始,我和我同事就开始关注在哪些方面我们可以进一步节省成本、节约能源,并思考如何更多地使用绿色能源,而不是传统能源。我们也计划在工厂屋顶安装太阳能电池板。所以在环保节能方面我们采取了很多行动。我们还更新了机器,换上了能耗更低的新机器。”Hardt说道。

Workers work in the Bosch Shenzhen plant. 工人在博世深圳工厂内工作。

“Last year we invested 8 million yuan (US$1.18 million) for the installation of VOC (volatile organic compound) machines to control emissions. We had external auditors on site for four months to check all the processes and emissions. Finally, we were certified, which means we are clean. Part of the investment was in the wastewater treatment machinery. We upgraded it and the water we discharge now is something like water you can drink. It is really very clean,” Morea explained.

“去年年底我们投资了大约800万元人民币,用来我们安装了挥发性有机化合物处理设备以控制排放。我们的外聘审计师连续四个月在现场检查所有流程以及排放。最后,我们的设备通过了审核认定,证明我们实现了生产洁净化。我们有部分投资用在了废水处理设备,我们升级了该设备,现在排放的水几乎和饮用水一样,这些水真的非常干净。”Morea介绍说。

Their efforts have reaped fruits. The company was nominated as one of the city’s top 100 companies for hazardous wastes management. “Currently a lot of companies are visiting us because they want to learn and understand how we achieved our targets,” said Morea.

他们的努力取得了丰硕的成果,2021年他们被评为深圳市100家危险废物规范化示范企业之一。“现在有很多公司来我们工厂参观,学习我们是如何实现这个目标的。”Morea说道。

Business going well with govt. support

一流营商环境助力业务增长

Like other companies, the Bosch Shenzhen plant was affected by the pandemic. However, with strong government support, the plant has been running well and also increased its sales.

跟其他公司一样,他们的业务也受到了疫情的影响,但是,在当地政府的大力支持下,博世深圳工厂不仅运行良好,销售还有所增长。

Some products of the Bosch Shenzhen plant. 博世深圳工厂生产的部分产品。

Though affected by the pandemic at the beginning of 2020, they produced a lot in the second half of the year. In 2021, the plant ran smoothly without really being affected.

2020年初,疫情对工厂的影响较为明显,但后半年工厂的产量大增。2021年,情况更加好转,工厂运营顺畅,基本不受疫情影响。

“Since we deliver to automotive manufacturers, we must deliver,” Morea explained. “And the local government understood that. They allowed us to produce. So, 200 employees decided to stay in the company. We purchased 100 additional beds for our dormitories, and these 200 employees decided to stay on board for one week to continue to work.”

“因为我们是汽车领域的制造商,所以我们必须交付相关产品。”Morea解释道。“当地政府了解这一情况,所以他们允许我们生产,我们的200名员工自愿留下来在工厂里生产。我们工厂有宿舍,然后我们额外购买了100张床位,这200名员工决定在公司闭环生产一周,继续工作。”

A machine at the Bosch Shenzhen plant. 博世深圳工厂内的一台机器。

According to Hardt, in general, their wiper blade business has not been affected by the pandemic but has actually achieved growth. “Over the last three years, our sales have been increasing. We now produce more wiper blades than ever before,” Hardt said.

Hardt介绍说,总的来说,他们的雨刷业务没有受到疫情的影响,还实现了增长。“在过去的三年里,我们的销售额一直在增长,我们的产量比以前大。”Hardt说道。

In terms of the wiper arm business, Hardt said that they were affected by the pandemic in the first half of the year. “But right now, we see that basically all the orders are being pushed into later this year. So, for the wiper arm business we also see a very heavy increase of orders, which is really good,” said Hardt.

关于雨刷杆业务,Hardt说他们在今年上半年受到了疫情的影响。“但现在看来,基本上所有订单都挤到了今年下半年了。所以,雨刷杆的订单也大幅增加,这对我们来说是一个好消息。”Hardt说道。

Marco Morea (L) and Sebastian Hardt show one of their products. Marco Morea(左)和Sebastian Hardt向记者展示他们的一个产品。

During the pandemic they also received government subsidies for social insurance, energy costs, electricity, medication and disinfection, according to Hardt.

Hardt介绍说,在疫情期间,他们还获得了政府在社会保险、能源成本、电力、药物和消毒等各个方面的补贴。